Sterilization methods of medical devices

Author:Baojie editor

Source:Anqing Baojie packaging co.,ltd

Release time:2022-07-19

In daily life, each sterilization method has different requirements for medical device packaging materials. For example, for medical devices with long catheters, ethylene oxide sterilization may be difficult to reach the official cavity center, thus affecting the sterilization effect; Some medical devices with sensitive electronic devices may be affected during gamma radiation or electron beam sterilization, so don't let the wrong sterilization method destroy your medical devices.

Once the items are cleaned, dried and inspected, those items that need to be disinfected must be packaged or placed in hard containers, and should be placed in the instrument tray / basket in accordance with the guidelines provided by AAMI and other professional organizations. These guidelines stipulate that instruments should be opened and items with removable parts should be disassembled, unless the equipment manufacturer or researcher provides specific instructions or test data to the opposite party; Complex instruments shall be prepared and disinfected according to the instructions and test data of the equipment manufacturer; Concave device is set for drainage; The heavy objects should be placed in a position that is not easy to damage fragile objects; The weight of the instrument group should be based on the design and density of the instrument and the distribution of metal mass. Although surgical instruments are no longer limited by specific sterilization weight, heavy metals are one of the reasons for wet packaging. After the sterilization cycle, the moisture in the box and tray. Other parameters that may affect drying are the density and design of the package.

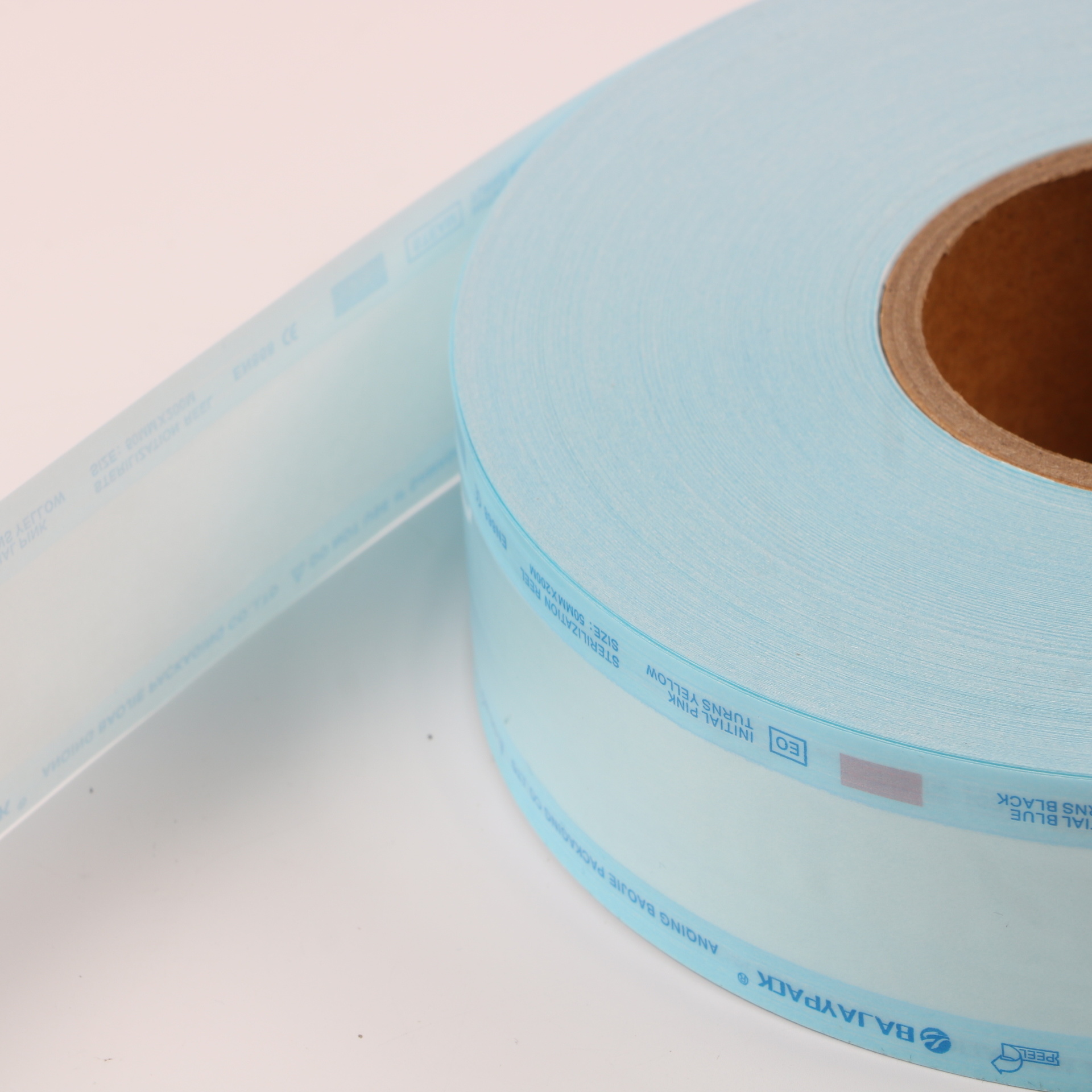

There are many options for maintaining the sterility of surgical instruments, including hard containers, open leather bags (such as medical self sealing bags or heat sealing sterilization bags and three-dimensional paper bags), flat roll bags or three-dimensional roll bags (such as paper plastic composite pipe design, which allows users to cut and seal both ends to form a bag), and sterilization packaging (woven and non-woven fabrics). Medical institutions may use all these packaging options. The packaging materials must allow the penetration of sterilizers, provide protection against contact pollution during operation, provide an effective barrier for microbial penetration, and maintain the sterility of processed products after sterilization. An ideal sterilization package should successfully address the effectiveness of barriers, penetrability (i.e., allowing the penetration of fungicides), permeability (e.g., allowing dissipation), ease of use, suspension, flexibility, durability, tear strength, toxicity, odor, waste disposal, wadding, cost, and transparency. Unacceptable packaging is used with foil paper, PVC and PVC kitchen transparent packaging or hydrogen peroxide gas plasma (such as linen and paper), and should not be used for medical packaging products.

In central processing, it can be in order or out of order (i.e. packaging at the same time). Packaging should be done so as to avoid tension and notches. Sequential packaging uses two sheets of paper in standard sterilization packaging, one after the other. This process creates a package in one package. Non sequential processes use two worksheets packaged at the same time, so packaging only needs to be performed once. The latter method provides multiple layers of protection for surgical instruments from pollution, and saves time because they are only wrapped once. Due to the strictness of operation in the equipment, multi-layer packaging is still a common practice, even though the barrier efficiency of single-layer packaging has been improved in the past few years. Written and graphical procedures for preparing packaged items should be in place and used by personnel when performing packaging procedures.

关键词: Medical,device,sterilization